In this training, safety professionals, technical personnel, engineers and managers will develop and understanding of the latest OSHA, ANSI, NFPA, RIA (industrial and collaborative robots) and ISO/EN requirements for industrial machine safety and risk assessment.

Learning Objectives

Upon completion of this training, you will be able to:

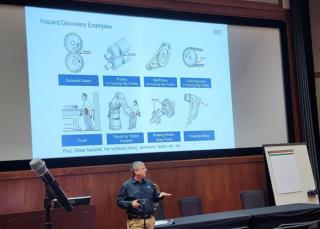

- Identify machine related workplace hazards

- Understand applicable U.S. machine safeguarding requirements

- Inspect and recommend compliant machine safeguarding

- Complete an OSHA/ANSI compliant risk assessment

- Understand advanced concepts, such as:

- Control reliability and functional safety

- Alternatives to Lock-out/Tag-out (LOTO – Hazardous Energy Controls)

- Industrial and collaborative robots

- Risk assessment and risk reduction strategies

- Liability and legal concerns

Instructor Bio

Ken Hackworth, PE, FS Eng. (TÜV Rheinland)

Ken Hackworth, PE has more than 30 years of experience in industrial controls and functional safety systems and is a licensed Professional Engineer (PE) and a certified Functional Safety Engineer. Ken received his Bachelor of Science in Electrical Engineering from The Ohio State University, is a subcommittee member of ANSI B11 safety standards and a member of the American Society of Safety Professionals.

Ken is experienced and certified in U.S. and international safety standards, including OSHA, ANSI, NFPA, RIA, and ISO/EN standards and specializes in machine safety engineering and compliance consulting. As a trainer for OSHA, Ohio BWC and several multi-national industrial clients, Ken enjoys training safety professionals, technical staff and business leaders in the latest technology and safety standards for industrial machinery.

Professional Development Credit: CEUs and PDHs

With our machine safety training programs, you have an opportunity to boost your expertise and the potential to earn professional development credits. Many organizations and states recognize seminar hours for Continuing Education Units (CEUs) and Professional Development Hours (PDHs). A CEU is typically equivalent to 10 hours of participation in a recognized continuing education program, and a PDH is usually equivalent to one hour of learning in a professional development activity. Check with your state or organization to confirm eligibility.

Training Notes

- Training is purchased per seat (per person). Training may not be shared with others unless it has been specifically arranged and agreed upon in writing before training begins. A PDF file of the training materials will be supplied just prior to the course.

- The training may be recorded. A copy of the recording is not typically provided unless it has been specifically arranged and agreed upon in writing before training begins. Any recordings are subject to technical limitations, settings, and conditions of the meeting platform (Teams, etc.) in place at the time of training.

- If we have any scheduling or topic changes, we will notify you as soon as possible.

Senior Manager –

“This was a great class…..a lot of information delivered in a smart and balanced manner I will definitely feel confident in using the class material when performing my next safety assessment.”

Technical Manager –

“This was not just the best safety training I’ve taken; this was the best training class I’ve ever taken…It was exactly what we needed and will help immensely when guarding our equipment.”

EH&S Manager –

“This was the most useful and detailed machine safety training that I’ve ever been a part of.”